Tesla - Product Design Integration

Non-Disclosure Agreement: I will only disclose non-proprietary information regarding my work at Tesla. All images are public knowledge.

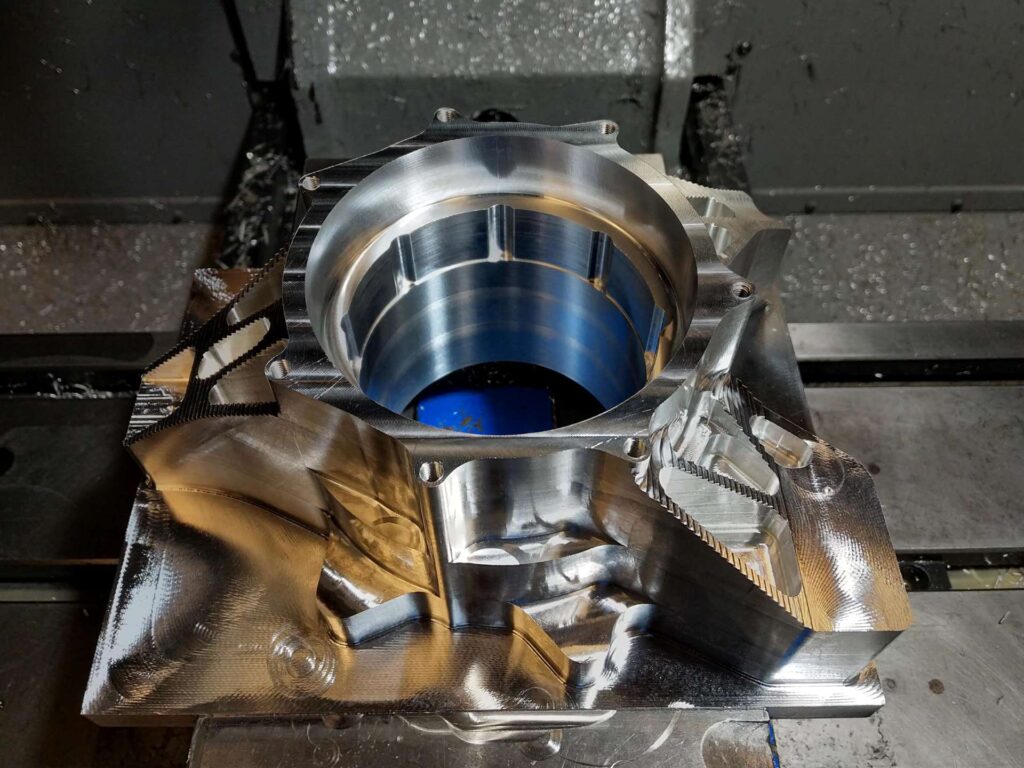

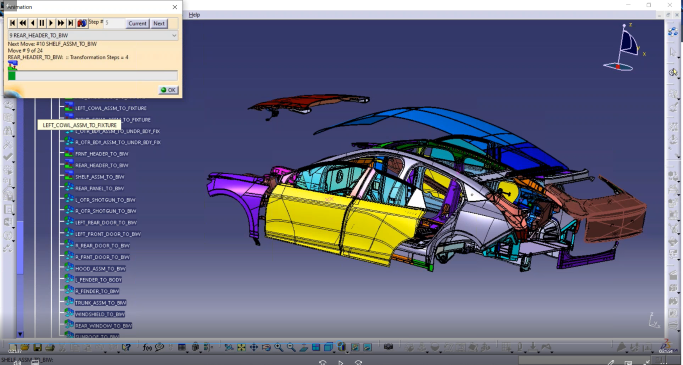

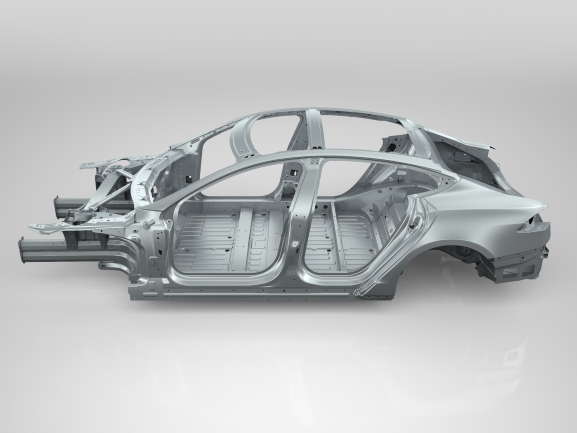

For my 6-month internship at Tesla, I was tasked with the daunting role of coordinating the integration of the Model S Plaid. My daily tasks comprised of identifying possible integration and packaging issues, then validating them with tolerance stack-up analyses. The analyses were completed with Monte Carlo simulations in 3DCS and Root Squared Sum (RSS). This role taught me vital technical communication skills to directly influence both the design and manufacturing of automotive body structures components. I was also in direct communication with oversea suppliers to drive the design of many fixtures (machining, welding, and checking fixtures).

My design philosophy focused on multidisciplinary aspects of a component. For every design change, I strove to understand the tolerance influence, cost, manufacturing and assembly process, material properties, fastener requirements, crash analysis, noise/vibrations, and many more.

My proudest achievements in the internship includes direct design influence for the Model S Plaid front and rear bumper systems, cross braces, and tow hitch. I also created the drawing with complete GD&T for the Model S Refresh body in white, along with leading the 3D GD&T creation for more than 30 other components.