Electric Motor Dynamometer

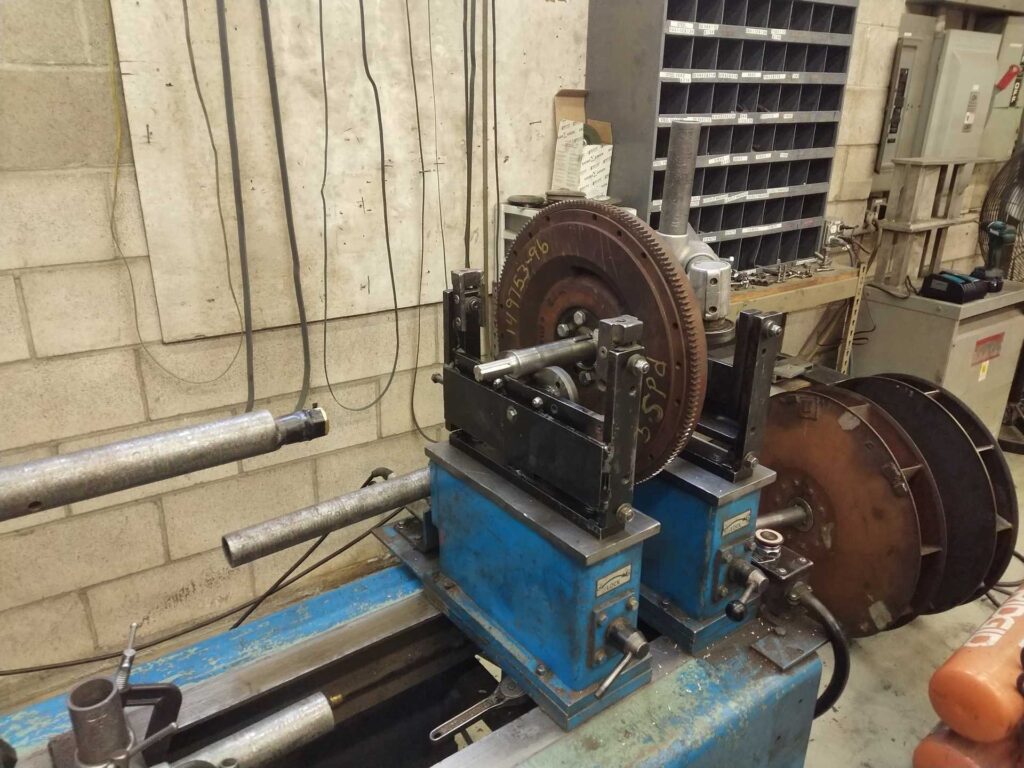

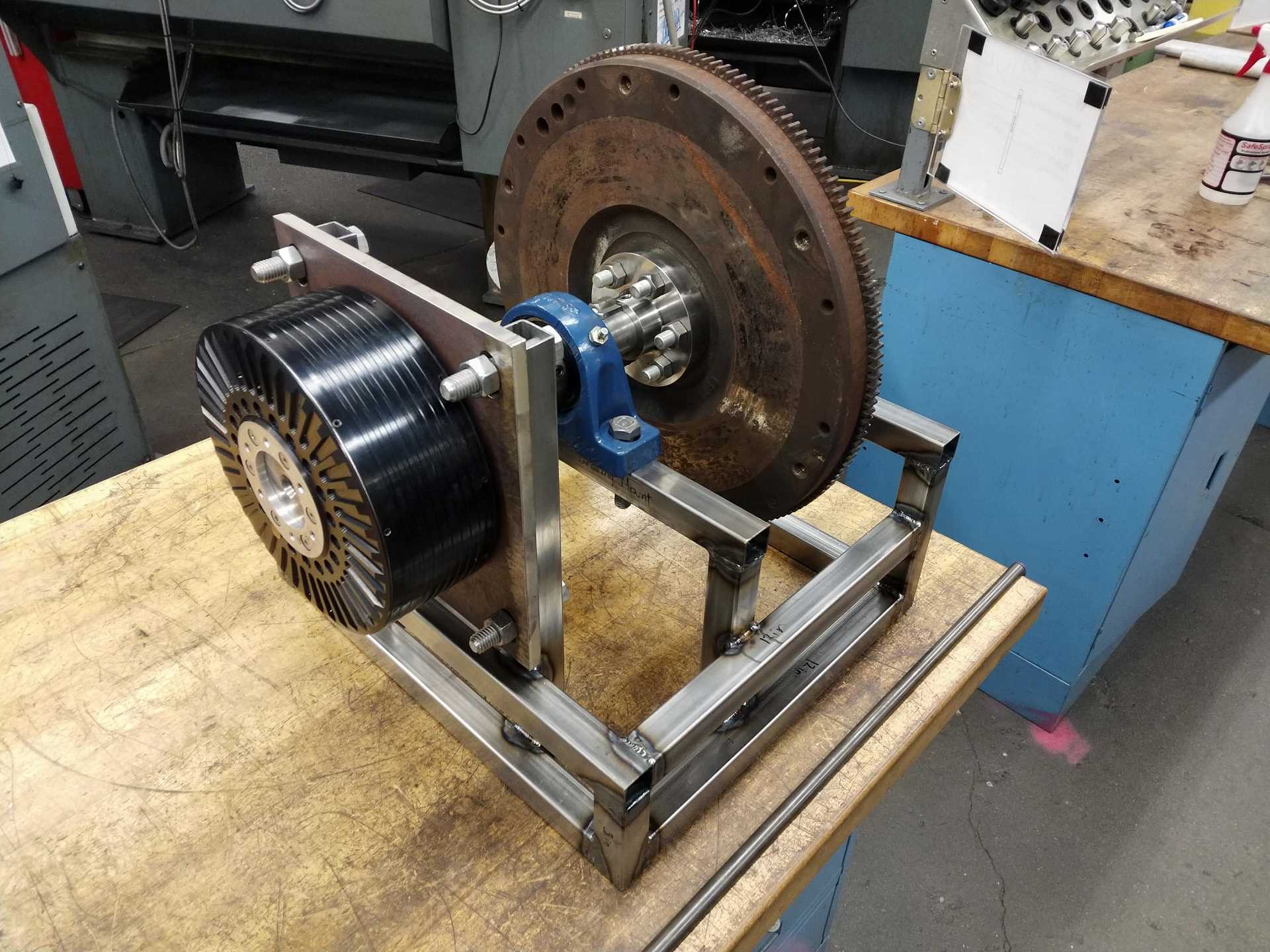

For my FSAE team, I designed and fabricated an inertial dynamometer (or dyno) to test our electric motor’s torque and speed output. It is important to accurately represent the car’s mass as a rotational load in order to test the motor correctly. Hand-calculation process is shown. The system was validated with fatigue loads to endure more than to 2,000 hours of testing, with the motor spinning up to 3,000 RPM.

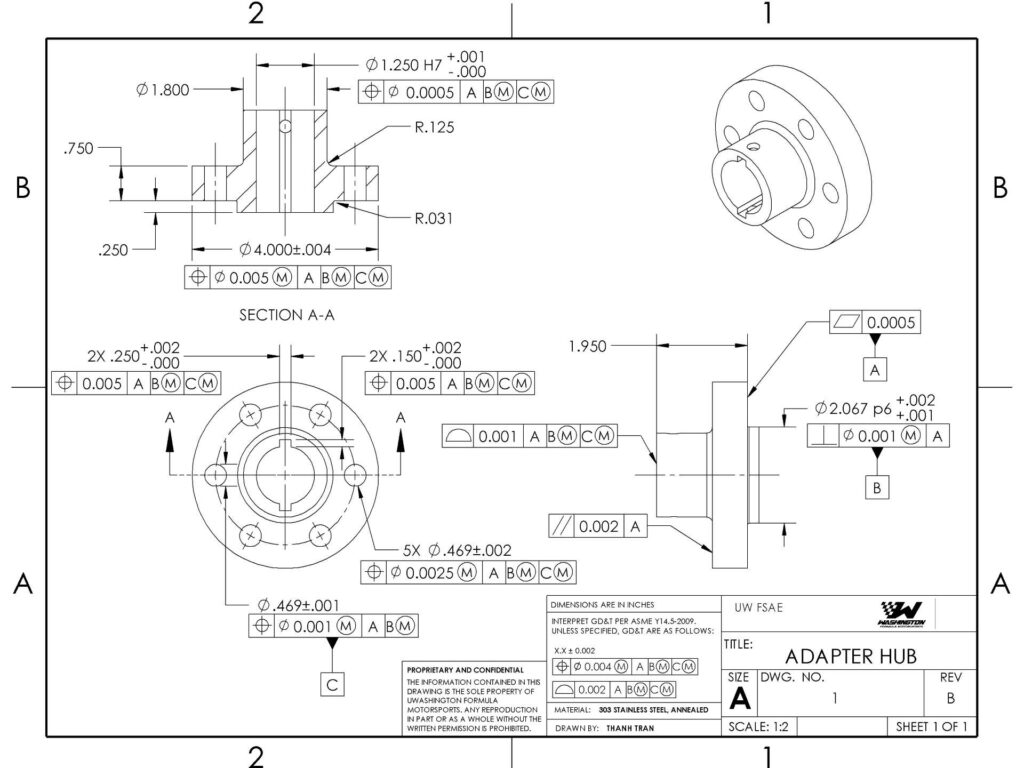

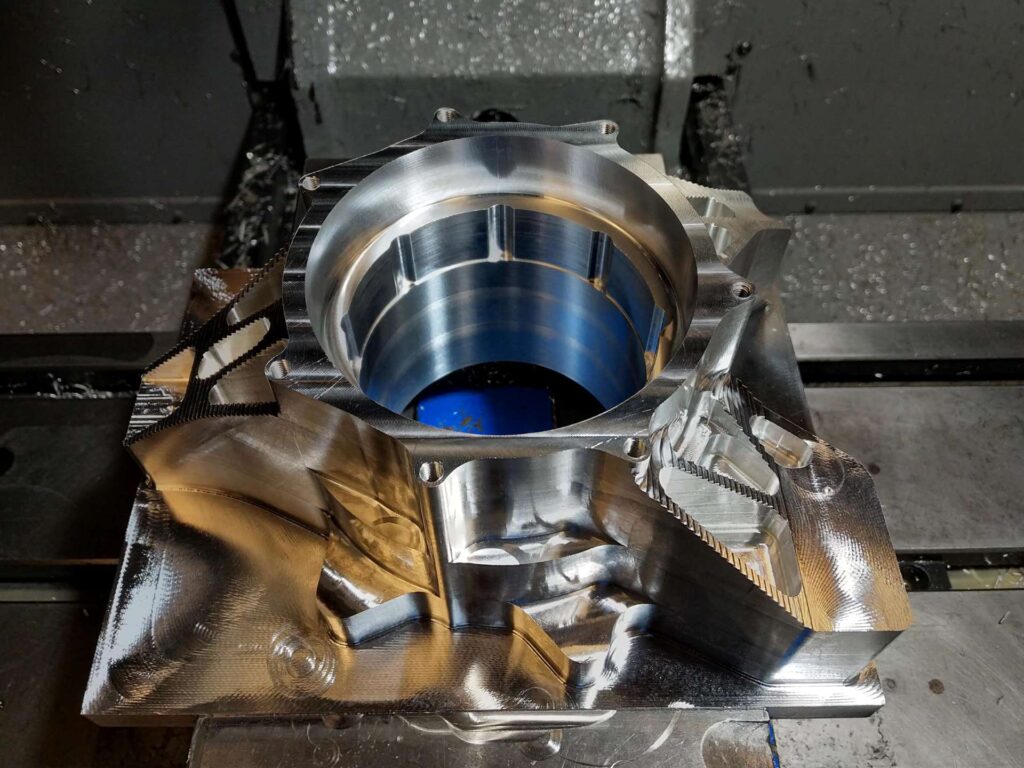

The rotating mass needed to be dynamically balanced to minimize vibrations of the structure. Shaft and hub components were CNC-machined to interference fits for excellent concentricity. The project is now assembled and ready for testing by the team.