FSAE Planetary Gearbox

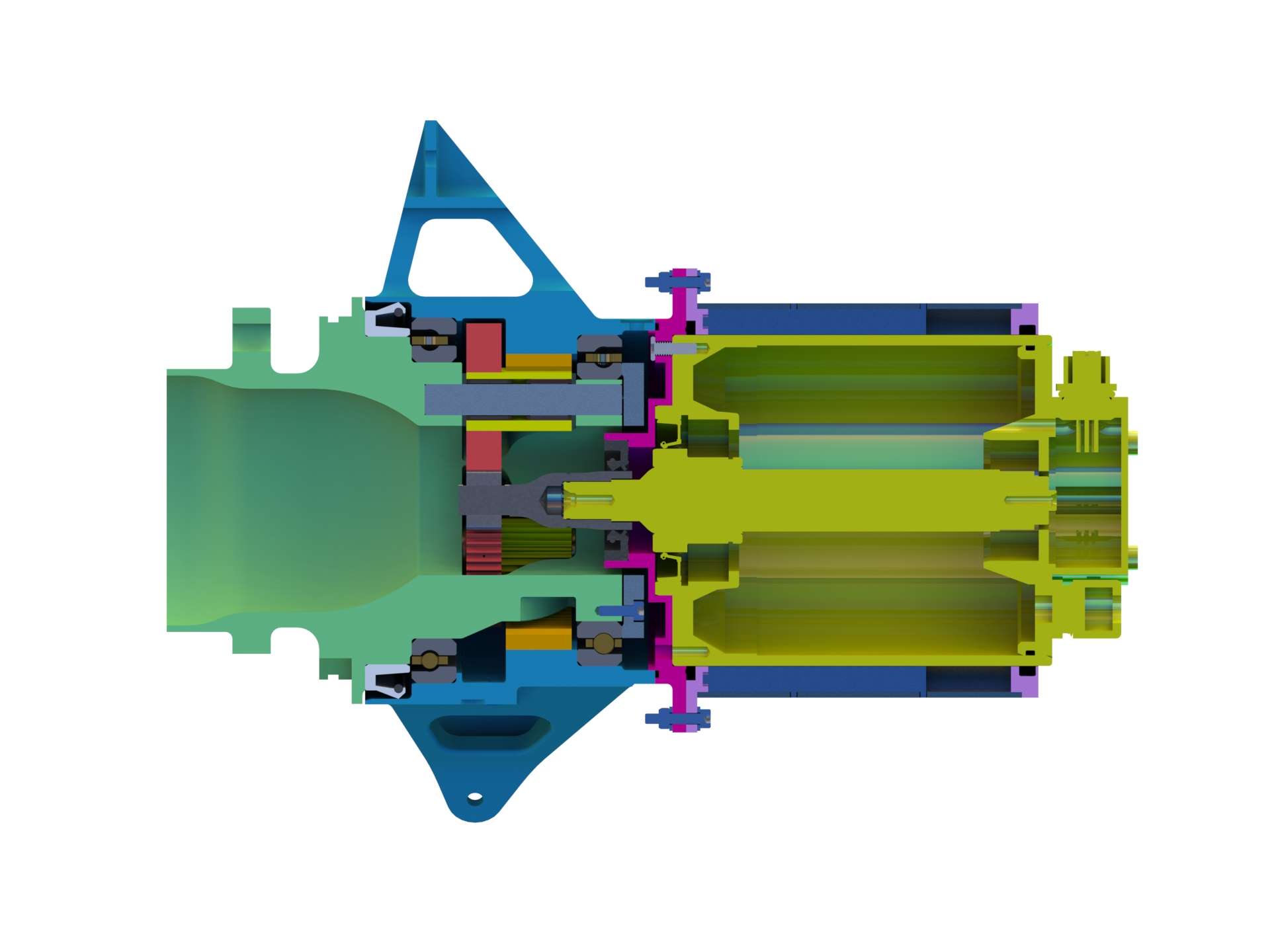

Single-Stage Planetary Gearbox Assembly

For our 2021 FSAE competition car, I was tasked with the assembly of the planetary gearbox, electric motor, and half-shaft. The three-phase Emrax 188 motor delivers torque through our planetary gearbox and half-shaft to power the wheels. With most components manufactured by teammates before COVID-19 lockdown, my tasks included fastener torque calculations, gears alignment, bearing & seal press fits, alignment jig machining, custom fastener machining, thread tear-out testing, resolver tuning, and many more.

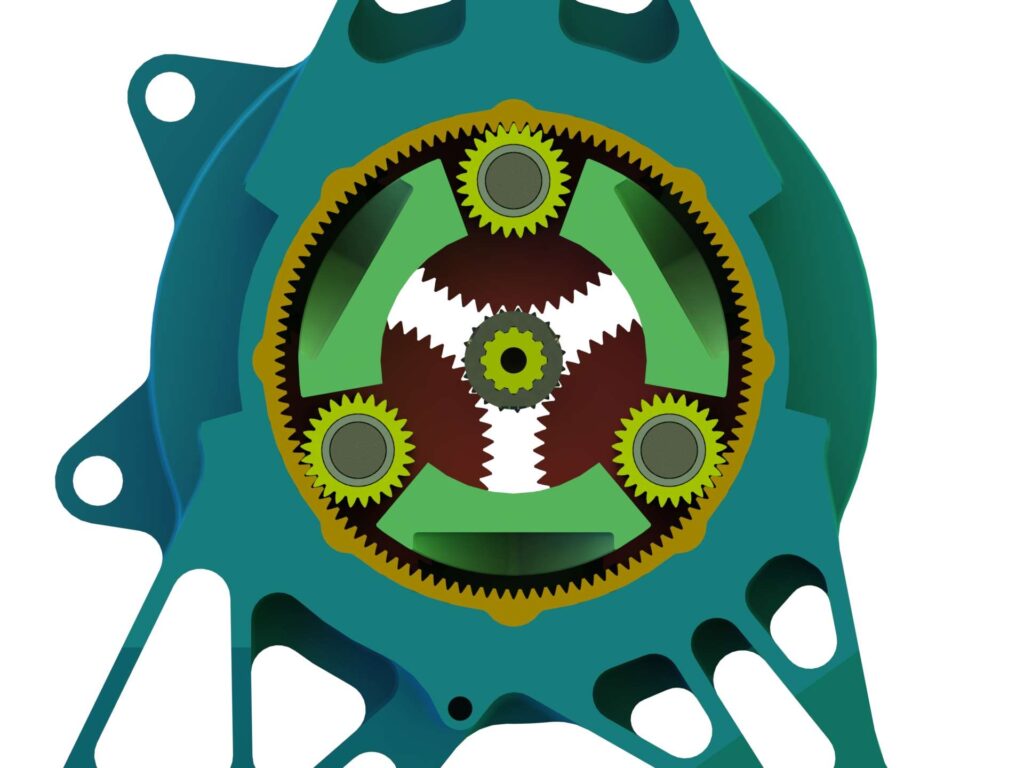

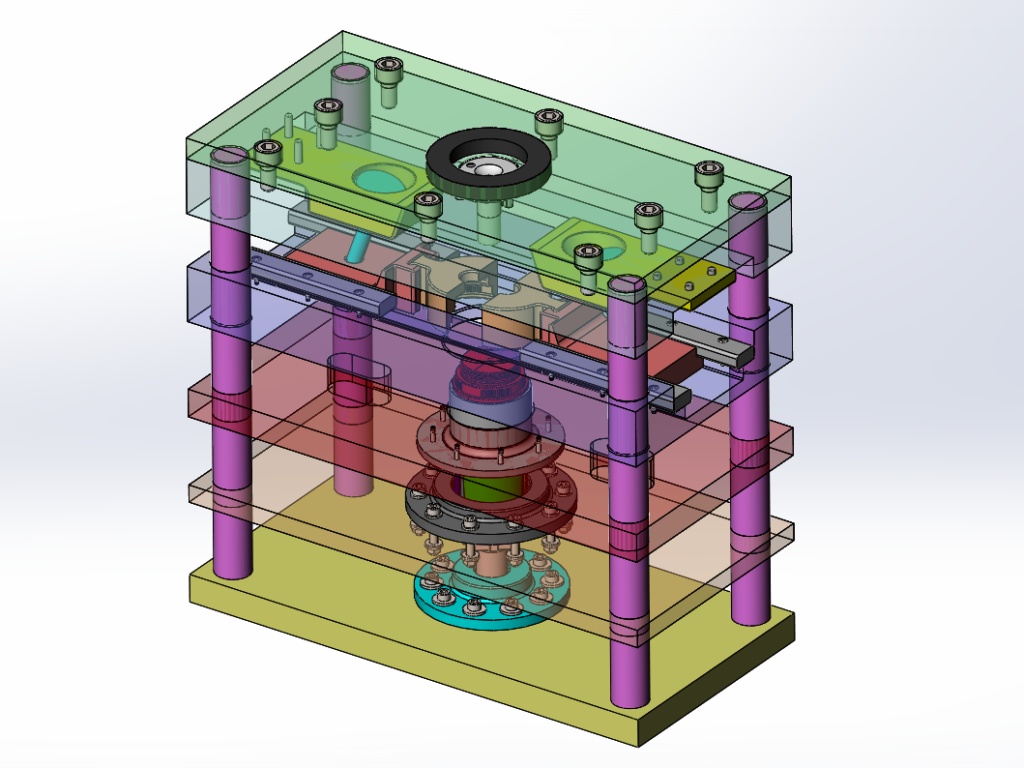

Two-Stage Gearbox Development

For our 2022 competition car, I am part of the drivetrain team tasked with designing internal-hub planetary gearbox for a 4WD upgrade using AMK electric motors. Our gears (ring, sun, big & small planets) are made of case-hardened aircraft grade steel. Blanks are machined and normalized in-house, with wire electro-discharge machining (EDM) and case-hardening processes done by our sponsor. I designed and machined components such as motor spline coupling, upright, and cooling system plates. I also completed redesigns for planetary gears for wire EDM and machined most gear blanks.