FSAE Suspension Uprights

Rear Uprights Development

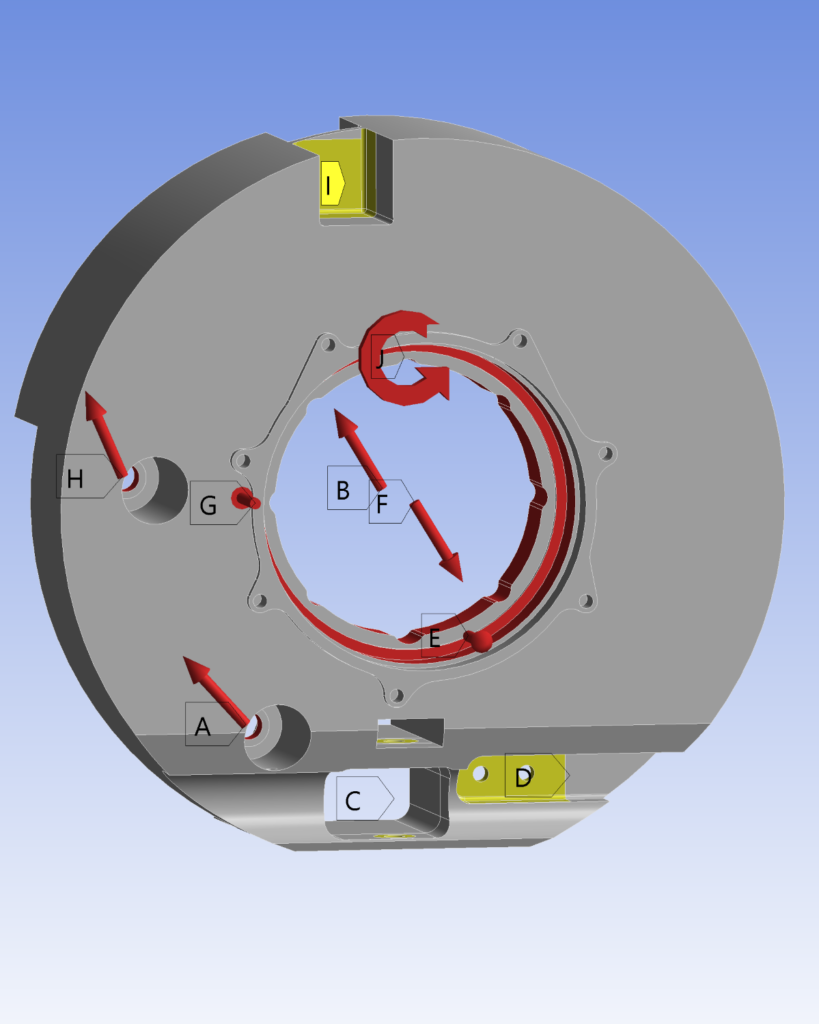

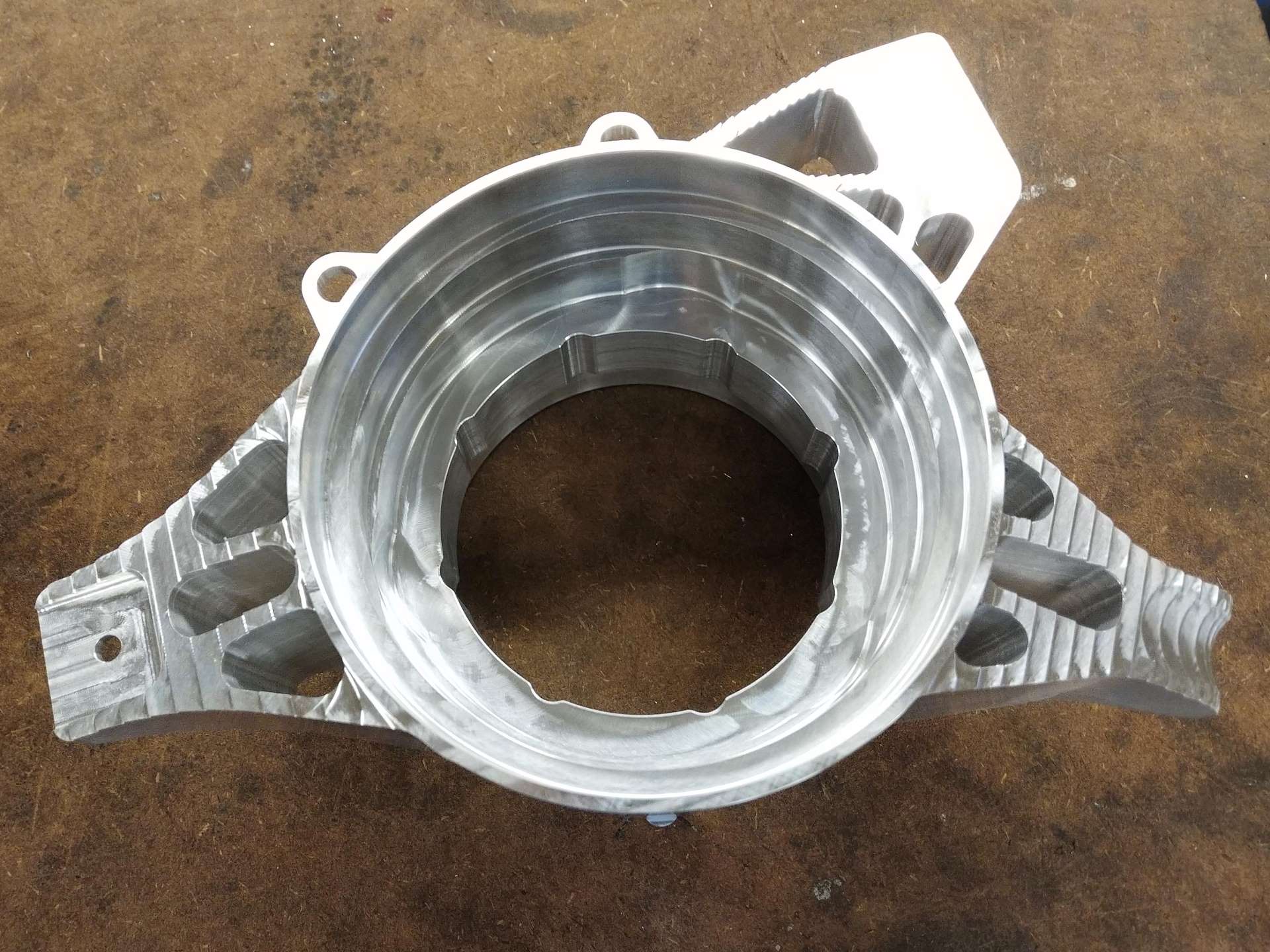

The FSAE upright holds the wheel hub and is vital to rigidly transfer the loads from the tires and brakes to the suspension system. This competition year, the upright serves an additional purpose of housing the compound planetary gearbox.

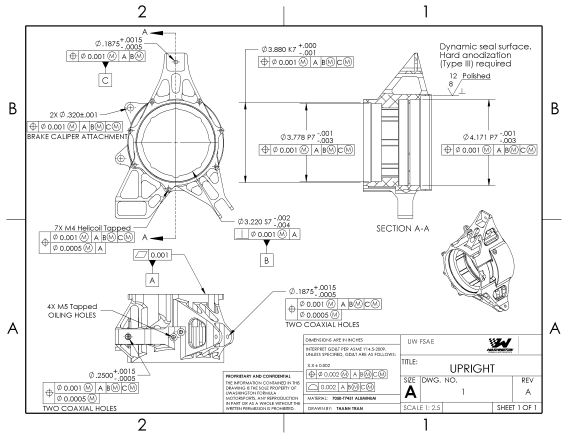

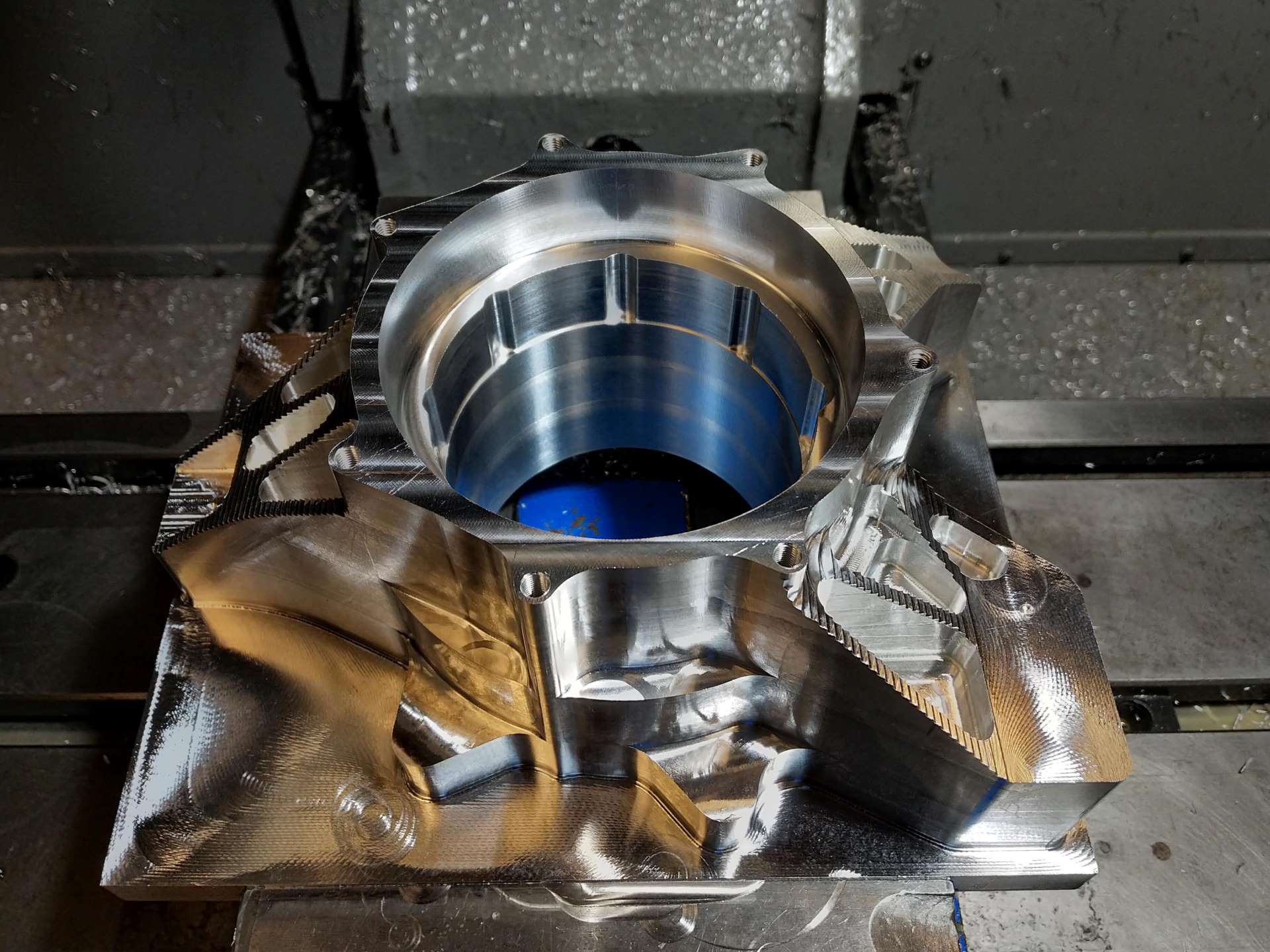

I was tasked with completing the redesign and FEA validation on the rear upright, and then machine the prototypes.

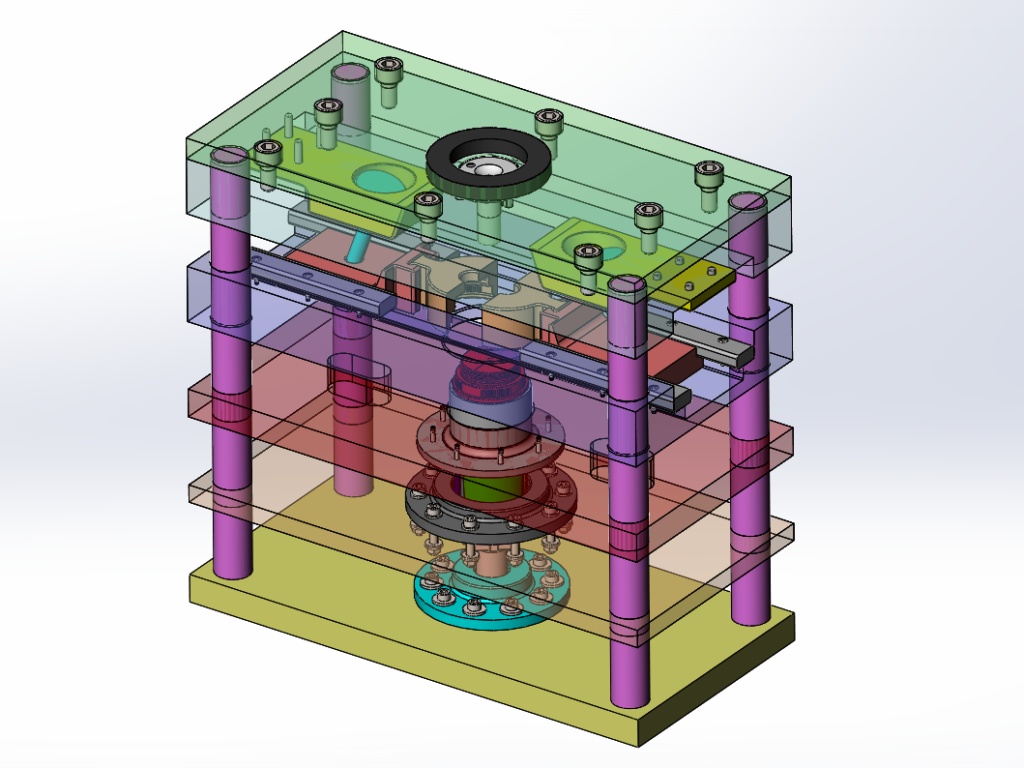

This upright possesses many critical tolerances such as bearing bores for the wheel hub and a shrink fit bore for the ring gear. Meticulous CMM measurements help validate that I have met the tolerances.

Front Uprights Development

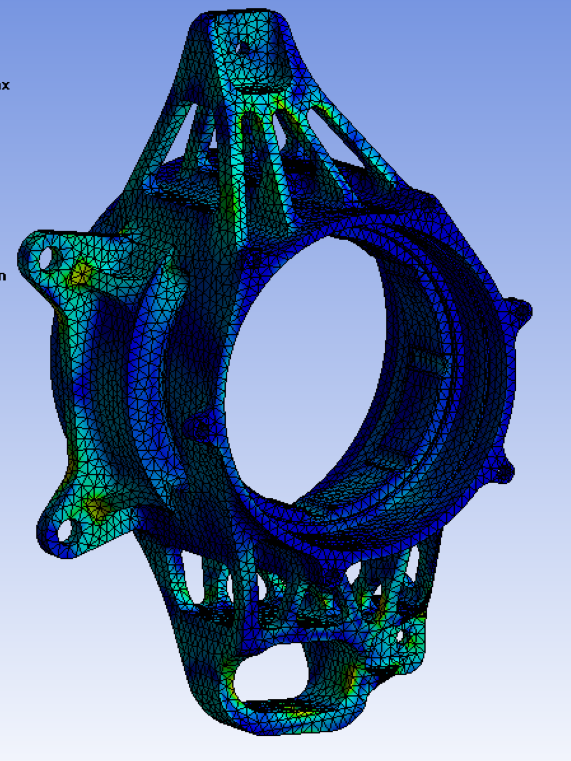

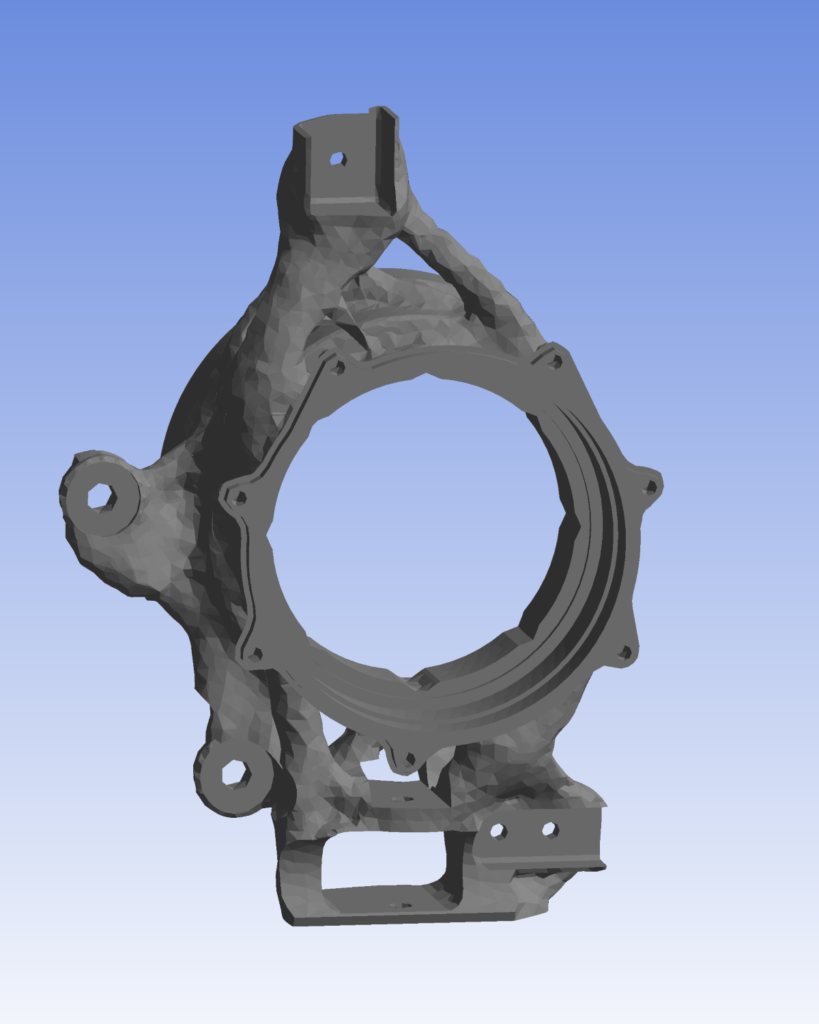

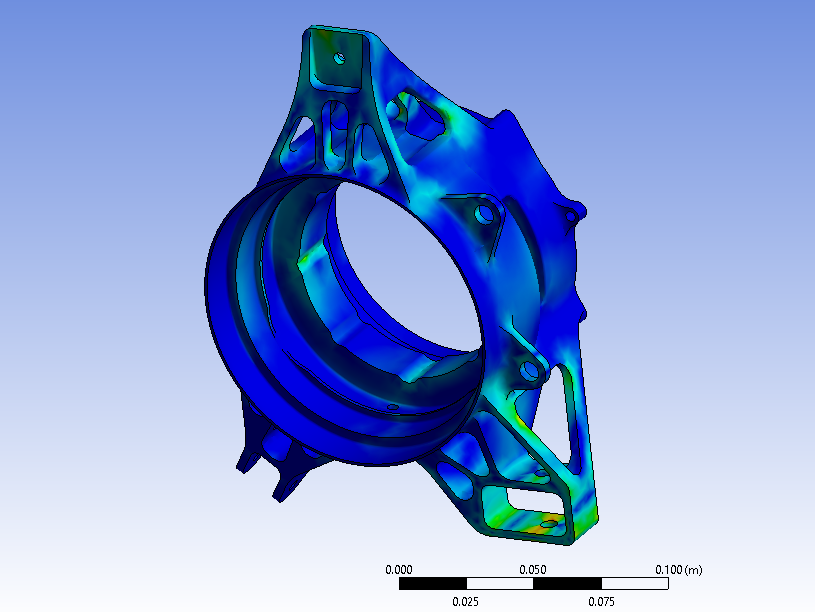

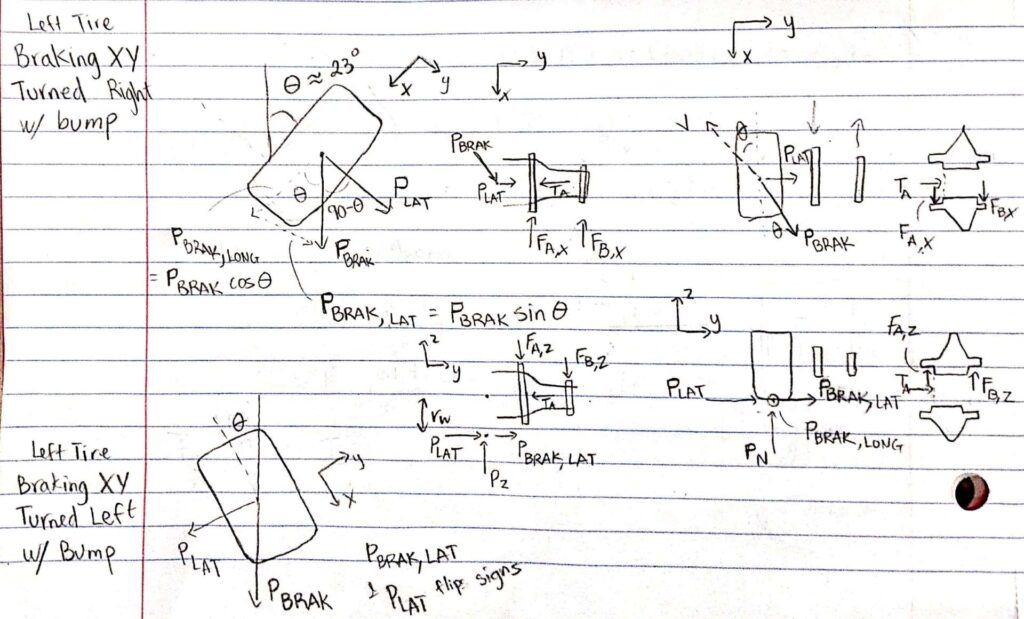

The front upright design is a unique challenge since it houses a steerable wheel. It undergoes accelerating, braking, bump, and cornering loads while being steered. My design plan for this part includes completing hand calculations, run topology optimization in ANSYS, then use optimized geometry as baseline to design a machinable 7075-T6 aluminum part. Future developments will include 3D-printing the part out of Ti-6Al-4V (titanium) to utilize the material’s high specific strength.